Product Data

Quality You Can Trust

ALCOTEX® Aluminum Composite Material is the premier choice for exterior cladding that will maximize the beauty of your structure while providing a sustainable product to prolong the life of your building.

Product Data

Coating Specifications

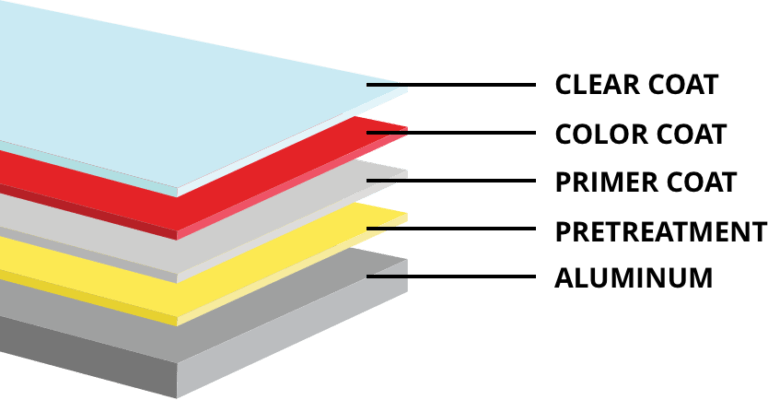

Alcotex® is coil coated with a polyvinylidene fluoride (PVdF) coating containing a minimum of 70% KYNAR 500®/HYLAR 5000® resins which meets or exceeds AAMA 2605 and AAMA 620 performance requirements.

- ASTM: American Society for Testing and Materials

- Kynar 500 is a registered trademark of Arkema Inc.

- Kynar 5000 is a registered trademark of Solvay Plastics.

PROPERTIES

TEST METHOD

PERFORMANCE

Dry Film Thickness

ASTM D1400

0.20 mil primer coat

0.80 mil color chart

0.50 mil clear coat (3 coat system)

Specular Glass @ 60°

Pencil Hardness

Flexibility T-bend

Adhesion

Reverse Impact

ASTM D523

ASTM D3363

ASTM D4145

ASTM D3359

ASTM D1308

25 – 35

HB Minimum

0-2T bend; No pick-off

No adhesion loss

No cracking or loss of adhesion

Acid Resistance

10% Muriatic Acid (15 minutes)

20% Sulfuric Acid (15 minutes)

ASTM D1308

ASTM D1308

No effect

No effect

Acid Rain Test

Kesternich SO-2, DIN 50018

15 cycles minimum

No objectives color change

Alkali Resistance

10%, 25% NaOH (1 hour)

ASTM D1308

No effect

Humidity Resistance

100% R.H. @ 100°F

ASTM D2247

Passes 4,000 hours

Salt Spray Resistance

5% Salt Fog @ 95°F

ASTM B117

Passes 4,000 hours

Color Retention

10 years @ 45°, South Florida

ASTM D2244

Maximum 5 fade

Chalk Resistance

10 years @ 45°, South Florida

ASTM D4214

Maximum 8 chalk

2 COAT (SOLID & MICA COLORS)

Both of these 2 coat finishes will typically consist of a 0.2 mil primer coat and a 0.8 mil color coat for a nominal dry film thickness of 1.0 mil.

3 COAT (METALLIC COLORS)

These 3 coat finishes will typically consist of a 0.2 mil primer coat, 0.8 mil color coat and a 0.5 mil clear coat for a nominal dry film thickness of 1.5 mil.

SRI / LRV

Solar Reflectance Index (SRI) numbers indicate how well the material reflects back instead of absorbing radiant energy and how well it radiates absorbed heat back into the environment.

Light Reflectance Value (LRV) numbers indicate the percentage of visible light reflected by the surface.

DIMENSIONS

Thickness: 4mm.

Width: 40”, 49” & 62”. Check with your local Alcotex® representative for availability.

Length: Within 196” is recommended for convenient handling and delivery.

ACM Features & Benefits

There are multiple features and benefits in using Alcotex® aluminum composite material. The ability to have design flexibility partnered with an extremely lightweight and rigid material that offers an endless choice of high performance finishes are just a few. Please contact us directly for more information.

Color Variety

Lightweight Panels

Environmentally Friendly

Design Flexibility

Testing Data

Alcotex® aluminum composite material has been extensively tested at fully accredited testing facilities in North America.

These test results meet or exceed the current testing requirements that should be expected to give the customer full confidence in selecting Alcotex® for their project. All of the fire and product test data reports are available to review upon request.

Testing Data

Fire Resistant

STANDARD

SUBJECT

RESULT

NFPA 285-23

ISMA Test -Intermediate-Scale Multistory Apparatus

Passed

ASTM E 119

Fire Test of Building Construction

and Materials

One and Two hour rated wall assembly successfully passed

ASTM E 84

Surface Burning Characteristics

of Building Materials

Flame Spread Index: 0

Smoke Developed Index: ≤ 5

UPITT Toxicity Test

Investigation of the Toxic Potency of Combustion Products

Passed

UBC 26-3

Form Plastic System

Passed

ASTM E 162

Surface Flammability of Materials Using a Radiant Heat Energy Source

Flame Spread Index:

Average: 0

Range: 0 to 0

ASTM E 648 / NFPA 253

Critical Radiant Flux of Floor-Covering Systems Using a Radiant Heat Energy Source

No Ignition

No Smoke

ASTM D 1929

Determining Ignition Temperature of Plastics

Spontaneous Ignition Temperature:

STI: 450°C (842°F)

Flash Ignition Temperature:

FTI: 440°C (824°F)

ASTM D 635

Time of Burning of Self-Supporting Plastics in a Horizontal Position

No Average Time Burning (ATB)

No Average Extent of Burning (AEB)

ASTM E 662

Specific Optical Density of Smoke Generated by Solid Materials

Flaming: 18.20

Non-flaming: 0.69

ASTM D 2015

Gross Calorific Value of Coal and Coke by the Adiabatic Bomb Calorimeter

4,080 BTU/lb.

CAN/ULC S102

Method of Test for Surface Burning Characteristics of Building Materials and Assemblies

Flame Spread Index: 0

Smoke Developed Index: 0

CAN/ULC S134

Standard Method of Fire Test of Exterior Wall Assemblies

Passed

Testing Data

General Property

TEST PROCEDURE

TEST METHOD

PERFORMANCE

Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

ASTM C 518

Resistance = 0.071 m² ˙ K / Watt

Conductivity = 14.085 Watt / m² ˙ K

Deflection of Temperature of Plastics under Flexural Load

ASTM D 648

Average Heat Deflection Temperature

Under Load at 0.010” deflection is 203.5°C

Coefficient of Linear Thermal Expansion of Plastics Between -30°C and 30°C

ASTM D 696

Average Thermal Expansion/Contraction is 2.51 x 10-5 mm/mm°C

Tension Testing of Metallic Materials – Yield Strength

ASTM E8

Average 43.1 N/mm²

Tension Testing of Metallic Materials – Tensile Strength

ASTM E8

Average 55.1 N/mm²

Tension Testing of Metallic Materials – Elongation

ASTM E8

Average 13.54%

Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions

ASTM E 90

Passed

Classification for Rating Sound Insulation

ASTM E 413

Passed

Shear Properties of Sandwich Core Materials

ASTM C 273

Average Shear Stress – 7.2 N/mm²

Average Shear Modulus – 0.8 N/mm²

Flatwise Tensile Strength of Sandwich Construction

ASTM C 297

Average Tensile Strength – 7.4 N/mm²

Climbing Drum Peel for Adhesives

ASTM D 1781

Average Peak Climbing Drum Peel:

Strength – 237.7 N˙mm/mm width

Flexural Properties of Sandwich Constructions

ASTM C 393

Average Shear Stress – 1.57 N/mm²

Testing Data

PVDF Coating Finish

TEST ITEM

TEST METHOD

PERFORMANCE

Color Uniformity

AAMA 2605

Samples must meet minimum dry-film

thickness requirements.

Specular Gloss (60º)

ASTM D 523

Using a 60 degree gloss meter, the samples must meet minimum dry film thickness requirements. Gloss values shall be within ± 5 units of the manufacturer’s specification.

Dry Film Hardness

ASTM D 3363

HB minimum using Eagle Turquoise Pencil.

No rupture of film.

Flexibility: T-Bend

ASTM D 4145

1-T

Adhesion – Dry, Wet, and Boiling Water

ASTM D 3359

Coating shall not pick off when subjected to a grid of 11 cuts x 11 cuts that are 1mm apart and taped with #600 Scotch Tape.

Impact Resistance

ASTM D 2794

Using a Gardner Variable Impact Tester with 5/8” mandrel, the coating must withstand reverse impact of 1.5 in-lb per mil substrate thickness. Coating shall adhere tightly to metal when subjected to #600 Scotch Tape pick-off test.

Abrasion Resistance

ASTM D 968

Using the falling sand method, the Abrasion Coefficient Value shall be a minimum of 40.

Mortar Resistance

ASTM C 207

Mortar prepared with 75 grams of building lime, 225 grams of dry sand, and approx. 100 grams of water shall dislodge easily from the painted surface. There shall be no loss of film adhesion or visual change.

Chalk Resistance

ASTM D 659

Chalking is measured on an exposed, unwashed painted surface and be no more than that represented by a No. 8 rating.

Chemical Resistance

ASTM D 1308

Utilizing 10% Muriatic Acid for an exposure time of 15 minutes, there shall be no loss of film adhesion or visual change when viewed by the unaided eye.

ASTM D 1308

Utilizing 20% Sulfuric Acid for an exposure time of 18 hours, there shall be no loss of film adhesion or visual change when viewed by the unaided eye.

ASTM D 2244

Utilizing 70% reagent grade Nitric Acid vapor for an exposure time of 30 minutes, there is a maximum color change of 5 Delta E units.

THE ALCOTEX® DIFFERENCE

There are many choices to consider when selecting architectural cladding, but there is only one choice when you are looking at aluminum composite material.

Alcotex® offers a fire resistant (FR) core material with all product testing performed at fully accredited North American testing facilities. Our production facility is ISO 9001 certified and we have an uncompromising dedication to quality.

Quality

Service

Value

Contact Details

Warranty

Alcotex® provides a comprehensive panel and finish warranty. The finish warranty ranges from 10-30 years depending on the coating selected.

It’s Easy to Get in Touch.

Interested in learning more about how Alcotex® could be the right choice for your project? Call us, email us, or fill out the form.